The well established brand precote® is known for its locking, sealing and clamping properties on threaded parts. The precote® products specially developed for pre-coating offer advantages in operational safety as well as in processing and efficiency in series production. Almost every car is using precote coatings in order to achieve the needed locking or sealing functions in battery packs, engines, gear boxes, interior, drive train, etc.

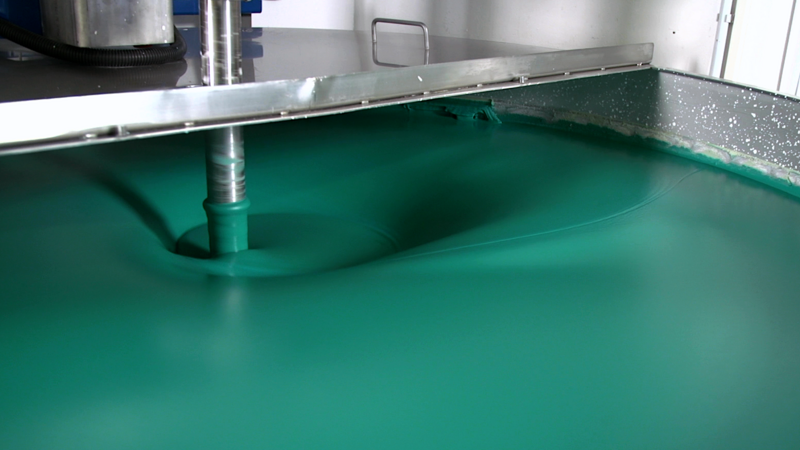

As an example - thread locking with precote®: By incorporating the unique microencapsulated components into a coating similar to a paint, precote® locking products are created. After application and drying, the result is a dry non-tacky coating that is permanently attached to the threaded part.

Advantages of precote® coated threaded parts:

-

captive coating

-

safe to operate

-

cost-efficient

-

constant assembly values

-

anti-corrosive

-

no additional mechanical sealing and locking devices necessary

-

coated parts can be stored for a long periode before use

-

automatic pre-coating through qualified and certified coating partners

The broad product portfolio is completed with dry lubrication technologies for metal, plastic and elastomere applications. Bonded coatings, also known as anti-friction coatings, offer many advantages compared to conventional oils and greases for high temperatures, applications with special hygiene requirements or highly loaded industrial machine elements. Our special tribo-coatings help you optimise the friction coefficients and sliding properties of your components and ensure longer lifetimes.

The advantages of anti-friction coatings:

- completely cover components and form a uniform lubricant layer

- no contamination due to dry lubrication

- reduction of friction and constant friction coefficients

- prevention or reduction of noise (no stick-slip)

- suitable for particularly high and low temperatures

- reliable lifetime lubrication