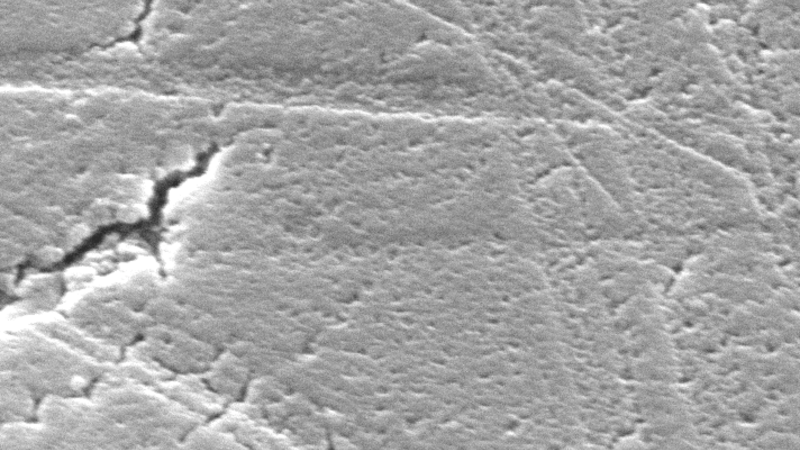

During the anodising process the H2SO4 re-attacks the anodic coating. The re-attack is directly proportional to temperature and time.

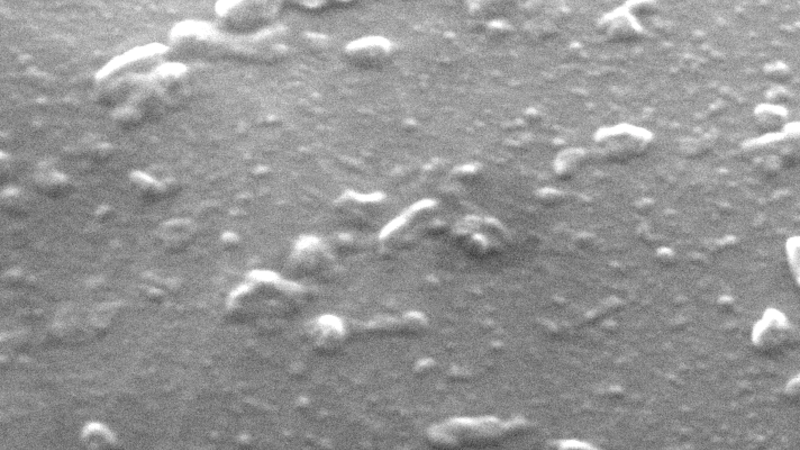

SurTec 313 contains organic acids able to protect the anodic coating in two ways:

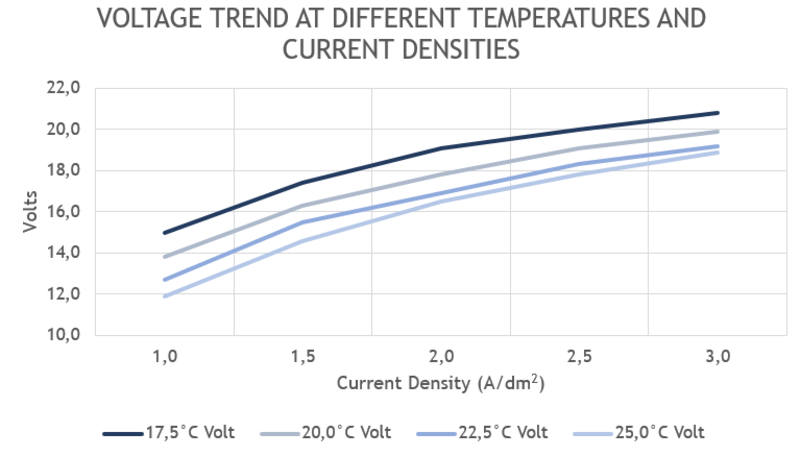

Therefore, the electrolyte temperature can be maintained higher than normal without damaging the anodic coating.

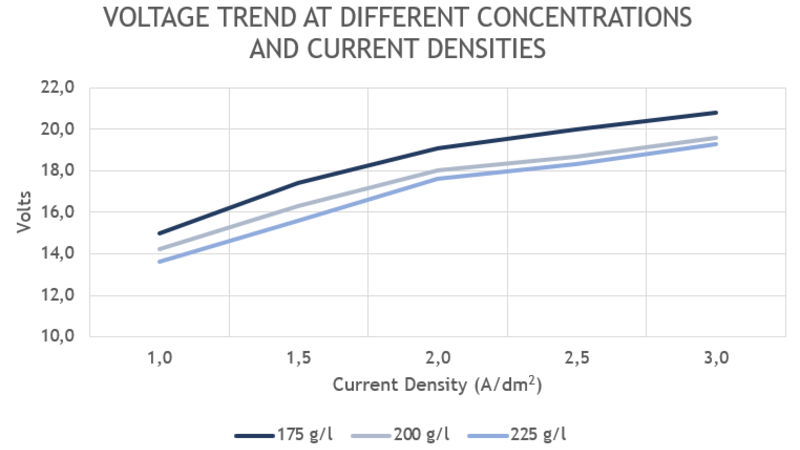

SurTec 313 also contains complexing agents that allow to work with a higher content of dissolved aluminium.

Energy savings:

Reduced managing costs and improved quality: